Do it yourself or hire a pro?

Attic ceiling insulation can cut your heating bills by more than just about any other home energy upgrade. In this article we will look at the different choices for attic insulation, from blown to batt, and from cellulose to fiberglass and rock or mineral wool.

We’ll cover recommended attic insulation levels, the importance of ventilation, how to make sure your contractor installs the right amount of blown in insulation, and health risks associated with vermiculite attic insulation.

Before we get to the main topic … a primer on attic insulation and R-values!

How does insulation work?

Insulation works by trapping tiny pockets of air or other gases between insulating solids such as fibers or foam. This combination of air and solids impedes the flow of heat through a space, by stopping heat conduction (heat transferred through solids or liquids, in this case the solid of the fiber or foam).

Because the air pockets are so small, insulation also stops convection, which is heat transferred through liquids or gases, in this case the air trapped in the fibers, or the air or gas trapped in the foam.

Heat does eventually make its way through the insulation, traveling from the warmer side to the colder side, but the better the attic insulation, the longer it takes heat to move through it. And don’t forget that, because heat rises, a lack of attic ceiling insulation means you’ll lose a lot more heat than for an equivalent wall space with no insulation.

What are R values?

The R value of insulation material is a measurement of how effective the insulation is at slowing down the natural transfer of heat from the warm surface to the cold surface.

R value is a function of the amount of heat transferred through an area, given a temperature differential. Since each of these three quantities can be specified in Imperial or metric measurements, R values are different between North America and the rest of the world, with Imperial (North American) values being approximately 5.67 times the metric values. In this article we will stick with North American R values.

You can generally add together the R values of different materials that are combined into an insulation layer. For example, if you have attic ceiling insulation consisting of 10 inches of fiberglass batt insulation between joists at R-3.14 per inch (total of R-31.4), and you blow in another 5 inches of fiberglass insulation at R-2.5 (total of R-12.5) your total insulation becomes R-43.9. The only problem with this rule is that the thicker the insulation layer, the more the upper attic insulation compresses the insulation below it, reducing its R value.

Attic blown in insulation vs. batt insulation:

installing attic insulation

You can install your own attic ceiling insulation, whether you choose batt insulation for attics, or blown insulation. While batts may on the surface appear easier, in my experience blown insulation is the faster way to go.

Batts are intended to fit between the joists of your attic ceiling. They should not be installed over top of existing attic blown in insulation.

If you already have attic blown in insulation, your best bet is to top up what you already have, either yourself or by hiring a professional. On the other hand, if your attic blown in insulation is damaged due to a leaky roof (for example, pressed down by shingle grit or bits of roofing wood), it may make more sense to remove it and install new insulation, either blown-in or batt. Just make sure you redo your roof first!

Blown cellulose insulation in my attic – blown in by yours truly!

Batts have a higher R value per inch if installed correctly. Correct installation means you have to be very careful to ensure there are no seam gaps between batts, and to ensure you don’t compress the batts when installing them. Loose-fitting batts mean heat will escape through the air spaces in the insulation, and compressed batts mean the R value is significantly reduced. In most do-it-yourself scenarios, it’s very hard to get that perfect fit, and so you wind up undermining the R value of the insulation due to gaps or areas where the insulation gets pressed too compactly around obstacles like wires and nails.

Attic blown in insulation can be installed much more quickly, and can be installed over top of either existing attic blown in insulation or batt insulation. If cost is a real factor for you, there are plenty of videos explaining how to blow your own insulation (I’ll share my experience on that further down – it worked great and saved us a bundle) but you should still consider getting quotes from an insulation company or two for attic blown in insulation, and compare that with your own estimate of do-it-yourself insulation.

You may be pleasantly surprised – installed attic blown in insulation is often cheaper than batt insulation purchased from your local building center, and that’s before you’ve installed the batts!

There are a couple of ways to add batt insulation to attic blown in insulation if you can’t afford to hire a company to help. Suppose you have 8 inches of blown in insulation (we’ll assume that’s R-2.2 per inch, or R-17.6) and you want to have at least R-30 everywhere:

- Take a rake into the attic and rake all the attic blown in insulation into an area equal to one half of the attic minus one joist width. Clear every last scrap of blown in insulation from the cleared section. Mound the insulation

- Install R-30 or higher batts (10 inches at R-3.14 or higher per inch) in the half of the attic where you removed the blown in insulation (leaving the one joist closest to the mounded insulation empty)

- Use your rake again to level the blown in insulation and remember to fill in the empty joist between the batt insulation and the mounded blown in insulation.

Alternatively, if the attic blown in insulation just covers to the level of the top of the joists, you can add batt insulation over top by placing the batts crosswise to the joists. Just remember not to leave any airspace between batts. Because the batts run crossways over the joists, they won’t compress the blown insulation that much and so won’t reduce its R value much.

When installing insulation yourself, be sure not to cover up any ventilation channels in your roof surface or soffits.

What R-value do I need for attic insulation?

The higher the R-value you use to insulate your attic ceiling, the more energy efficient your house will be. Don’t skimp on this expense! In general, in extremely cold areas such as most of the Canadian prairies and north, and the northern US plains states, you should strive for R-60 or higher, and even the southernmost parts of the US should strive for at least R-25 (remember, attic ceiling insulation not only helps hold the heat in during cold weather, it slows the heat entering your house from your attic in hot weather).

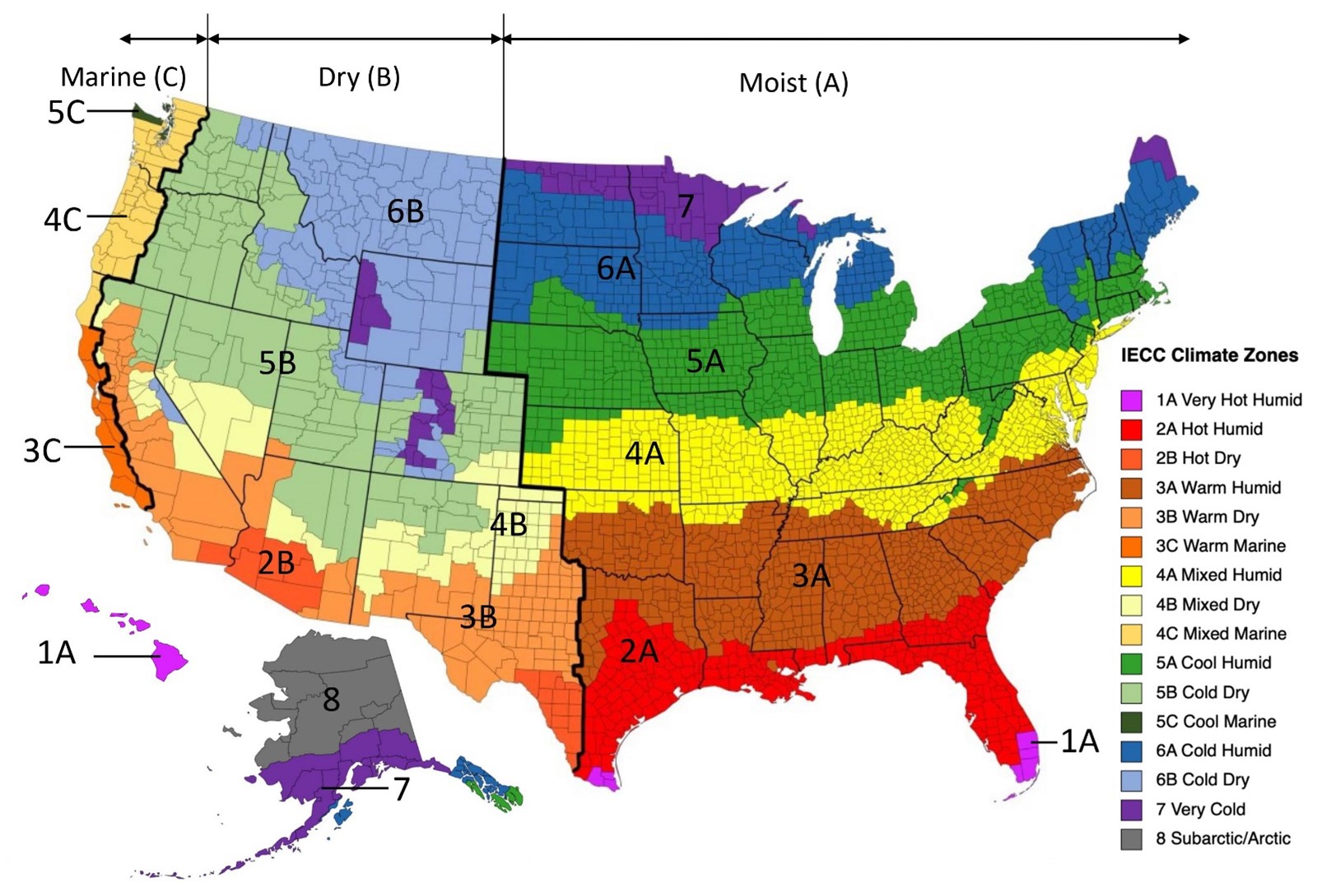

Attic ceiling insulation map for US heating zones. Source: EnergyStar.gov Insulation.

The map at left shows heating zones for the US, where recommended attic ceiling insulation levels for fossil gas, heat pump, or fuel-oil heating are R-30 for zone 1 (Hawaii and the southern tips of Florida and Texas), R-49 for zones 2 and 3, and R60 for all colder zones. Remember that these are minimum recommended levels; more is almost always better. For really cold areas like the northern midwest, far northeast, or Alaska, I would recommend targetting R80 if you can achieve it. I installed close to R80 in my attic and it wasn’t that much more money or effort than doing R60.

For electric heat you should always install as much attic insulation as possible, because even the most energy efficient electric heat is more expensive than natural gas, oil, or wood stove heat. Strive for at least R-60 regardless of the zone you live in.

The importance of ventilation

Make sure you or your installer do not cover up any existing attic ventilation, from roof vents, side wall vents, or soffit vents, when installing attic ceiling insulaiton.

In fact, when you are reinsulating your attic it’s a good time to consider adding ventilation to soffit vents if you do not already have enough (you can never have too much roof ventilation, as long as you don’t let water in!).

For soffit vents, install rigid plastic ventilation baffles, available at your building center, from the soffit vent up along the roof line so that the top of each baffle clears the top of the added insulation.

Adequate ventilation helps keep your attic from getting too hot in summer, and keeps a good airflow to prevent humidity build-up in cooler weather. One smart solution is to install a solar powered attic vent. These vents use a small solar panel, in some cases along with wind power that turns the vent itself, to exhaust heat from your attic. Because solar power is strongest on hot sunny days, these solar attic fans help keep the attic cool on such days.

Checking the installation of attic blown in insulation

If you are half-way handy and are having insulation blown in by the pros, nail a few thin strips of wood upright against the joists so that they reach at least 8 inches above the level of attic ceiling insulation you’re paying to have blown in. Then mark the level of agreed insulation (measuring from the top of the ceiling between joists, not the top of the joists) with a red permanent marker, and mark lines two inches above and below that line. That way, you can climb up into your attic when the job is done and check whether the installer got the correct level of insulation. If there are a few areas that are below the red line, don’t worry too much as long as they aren’t below the lower black line. These markers will also remind your installer to do a thorough job – when they know their work is being measured, they tend to be more careful.

If your installers are true professionals, it’s likely they will staple pre-printed insulation rulers to the walls or hanging from the joists themselves. Not only do they want to show you they’ve done the job right, they need to be able to measure it themselves.

What’s the best attic insulation?

There really is no single type of insulation that is the best attic insulation. Avoid rigid or sprayed foam insulation in attics, as you do not want a vapor barrier between your attic and your living space, and foam panels provide some level of vapor barrier, while sprayed foam creates a total vapor barrier. Blown in fiberglass or cellulose, or fiberglass batts (such as Pink Panther insulation), or rock wool batts (such as Roxul) are all suitable materials. The key considerations are R value per inch, and inches installed. Typical R-values for different types of insulation are:

| Insulation Materials | Typical R-value range |

| Fiberglass Batt (e.g. Pink Panther insulation) | 3.1-3.4 |

| Fiberglass Blown (attic) | 2.2-4.3 |

| Rock Wool Batt | 3.1-3.4 |

| Rock Wool Blown (attic) | 3.1-4.0 |

| Cellulose Blown (attic) | 3.2-3.7 |

| Vermiculite | 2.13 |

See note below on vermiculite – it’s not currently available; I include it only to show its R value in case you already have it, in comparison to what you could have if you upgraded your attic ceiling insulation.

My own preference, having dealt with several types of insulation, is to go for cellulose attic insulation. I had an attic with fiberglass insulation and every time I went up there to do maintenance I had to fully cover my body, and wear a mask and goggles, because even if I barely moved up there, particles of fiberglass would get into my eyes, my lungs, and onto my skin, and cause irritation for several hours. Once I moved to blown cellulose attic insulation I had no such problems.

Vermiculite attic insulation

Vermiculite is a naturally occurring mineral which expands into a very lightweight material when heated. Vermiculite pellets were commonly used to insulate attics until the 1990’s. Vermiculite was thought to be harmless, and indeed in its pure state there are no health risks posed by vermiculite.

However, one of the main mines where vermiculite was mined until 1990 was a mine near Libby, Montana, which also contained a natural deposit of asbestos. As a result, vermiculite from this mine became contaminated with asbestos. The mine was shut down and current sources of finished vermiculite are low in contaminants. However, due to both the low R-value of vermiculite compared to other blown or batt insulation, and to ongoing concerns about contamination (even at low levels), I would suggest avoiding it altogether.

Zonolite insulation, a brand manufactured by W.R. Grace & Co until the early 1980’s, is one type of attic insulation made from vermiculite. Zonolite insulation originated from the Libby mine, but the manufacturer claims that its manufacturing process removed most of the asbestos fibers and that the resulting product posed no significant health risks. Zonolite insulation was discontinued for economic reasons only.

However, there are an estimated 15 to 35 million homes in the US with Zonolite insulation installed in their attics or walls. As a result of a class action lawsuit against W.R. Grace, homeowners with Zonolite insulation installed are eligible for a rebate of 55% of removal and remediation costs of the insulation, provided the work is done by certified professionals, up to a maximum rebate of $7,500. As of November 2023, this rebate appears to be still available.

If you do have Zonolite insulation or other vermiculite attic insulation installed already, do not disturb it and avoid going into the attic at all. You are unlikely to experience any health issues if the insulation is left in place undisturbed and you stay out of the attic. The real risks come when you breathe the attic air or disturb the vermiculite attic insulation by entering the attic.

If you are unsure whether you have asbestos insulation in your attic, see the information on Asbestos.com (brought to you by the Mesothelioma Center) on How to check for asbestos in my home. Although you can gather samples for testing for asbestos content, even the act of gathering the insulation sample can be hazardous, so read up first.

If you need to do a ceiling renovation that requires insulation to be moved or removed, hire a licensed asbestos insulation removal company to test, and if necessary remove, the vermiculite attic insulation. Asbestos is an extremely toxic compound whose ill health effects can take years or decades to show up.

Do-It-Yourself blown insulation

I had a home energy audit done in early 2023 and one of the highlighted areas to improve was my attic ceiling insulation. I had about 8 inches of blown insulation – about 2-3 inches of very old cellulose, and another 5-6 inches of blown fiberglass. Because of some previous leaks in the attic, the cellulose was somewhat mildewy and the insulation had gotten pressed down, so I spent several painful hours in the attic bagging the insulation to remove it. For $50 in tipping fees and $40 in truck rental I was able to get rid of the old insulation at the local dump.

Before installing the cellulose I purchased attic vent baffles, which are shaped in cross section like a very squashed W. You tuck them in between the rafters running as close to the soffits as you can. They’re typically 4 feet long. Since I was adding a lot of insulation, I added two baffles heel to toe in each rafter. These baffles allow air to flow freely between the baffle and the roof, even after insulation is added. They’re easy to install – just tuck in and staple in place.

I also built a box around my attic hatch – covering a floor area one foot wide all around the opening, and adding plywood walls to a height of 24 inches, so that I could blow 28-30 inches of insulation and still have a couple of inches to spare on the wall (8 inches of the 28-30 would be between the joists, so below the start of the box walls). I didn’t install the last wall (the one facing the biggest area of the attic) until close to the end of the attic insulation blowing effort.

I chose a reputable brand of cellulose blown insulation available at my local Lowes store (okay, not my local one – it took calls to three stores to find one that had some in stock). Typically when you buy 10 or more bales of blown insulation from a big box store, they will rent you the blower at no extra charge. The store with the insulation didn’t have a blower, and the store with the blower didn’t have insulation, so there was a bit of a phoning around to get one store to agree to lend me the blower (“We’re all the same company”, one of the employees told me.) We rented another van, spent an hour driving around town to pick up the bales and the gear, and started on the work.

Installing wasn’t terribly complicated. You drag a very long white hose up into the attic. You run it out a door or window towards wherever you’ve installed the blower. In our case we left the blower in the van; it took four of us (my friend and I and two Lowes employees) to get it into the van, so there was no way two of us would get it out. You attach the hose to the base of the blower, and plug the blower in. The system had a very long cord with a switch at the end; the idea is the person doing the blowing can turn the blower on or off remotely. The switch didn’t work for us – the blower stayed on – so we had to communicate by phoning each other (not easy to hear a phone ring when you’re wearing ear protection and the machine is humming away loudly).

The person at the blower cuts open the bales of cellulose and dumps the cellulose into the blower, breaking it apart so it feeds properly into the hopper. From there the cellulose is shredded and broken apart, then blown through the hose. The hose is spiral-ribbed, and this ribbing, as the insulation passes through it, causes the insulation to expand. The person in the attic (in this case me) holds the hose and sprays the foam to the far corners of the attic first, progressively backing up towards the attic hatch.

It took us about three hours to do the blowing. At one point we ran out of insulation and I realized there were a few areas that weren’t quite high enough; off to the building center we went to buy eight more bales. The whole job was done in about eight hours, at a cost of roughly $800 for the insulation. Compare that to $2000-4000 for a professional job, based on the quotes I was seeing on contractor selection websites.

I don’t recommend this for everyone – you need to be handy, and willing to put up with the unpleasantness of working in an old dusty (or even health-compromising) attic, and have some time on your hands. But if the choice is between not doing it, and doing yourself, it’s worth a try.

I agree with your point of view . definitely like any other method of insulation this probably would be the most efficient way of saving on your electric bill.

Great info clearly explained. Thank you so much!!!

I think it is really interesting that the better the insulation is the longer it takes the heat to escape the house. Heating a house is expensive. I will definitely look into getting really good insulation for my new house I am building next spring. Thanks for the information!